You see, machining has always been all about precision. Yet with parts becoming more and more complex, and industries demanding tighter tolerances, the tried-and-true methods of keeping parts fixed just don’t work anymore. That’s when the 5-axis vise comes quietly into play, and changes everything.

We’re not referring to minor enhancements. We’re referring to machining freedom, substantial time savings, and the type of flexibility that allows you to drive your shop’s productivity to the next level. Whether you’ve used a 2 jaw vise or some other conventional machine vise, you’ll likely understand why this innovative setup is being touted as key to today’s applications.

Let’s dissect why this diminutive but potent piece of workholding equipment is becoming more popular throughout workshops globally, and why it may be the most intelligent update you didn’t realize you needed.

Precision Matters: How a 5-Axis Vise Enhances Accuracy

When you’re producing high-worth parts, even minute differences can cause serious losses, time and money. That’s where a 5-axis vise truly comes into play. There are some positioning errors that traditional vises introduce during re-flipping or re-clamping of parts. But with a 5-axis configuration, there is minimal repositioning required, which tends to enhance your machining precision.

The low-profile configuration provides more access to several faces of the part so that there are fewer tool changes and no compromise on the finish surface. With repeatable clamping included, these vises maintain part alignment to remain tight through cycles. Whether it’s aerospace parts or medical devices, precision is the game. A 5-axis machining-designed machine vise provides that advantage, and then some, by putting control in the hands of the operator with minimal effort.

The Evolution from Traditional to Modern Vises

In the beginning, machining was very much carried out using 2 jaw vises, simple but reliable devices that performed very well on flat, uncomplicated parts. But as component complexity increased, limitations began to manifest. Consider limited access, additional setups, and compromised accuracy.

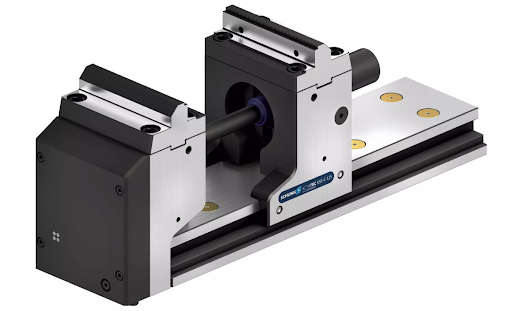

In comes the 5-axis vise, designed to swivel and clamp parts down tightly from several directions while providing full cutting access. In contrast to previous machine vise designs, these newer vise models allow up to five sides of a part to be machined with a single setup. Fewer setups translate to fewer opportunities for mistakes and quicker production times. And in a manufacturing universe where efficiency is being pursued around the clock, that’s a major plus.

The Secret Tool: Access from Every Direction

One of the 5-axis vise main benefits is its small footprint and low-profile jaw. What does that translate to in practical terms? More access to the part. In contrast to a 2 jaw vise, which can impede tool access in some directions, the 5-axis configuration keeps the part in place but doesn’t interfere.

With less clamping surface interference, machinists have better spindle and tooling entry points. Intricate geometry? Deep pockets? Angled cuts? All within reach, without reclamping or remeasuring. This added access frequently eliminates secondary operations, resulting in a smoother, faster, and more consistent process.

Better Precision = Better Parts

Accuracy isn’t solely about the toolpath, it’s also a matter of part holding. As a component travels, even a small distance, as it is machined, accuracy takes a hit. The 5-axis vise provides constant pressure and secure clamping, minimizing the likelihood of part slippage or vibration.

That stability provides improved repeatability and finish quality, particularly in multi-axis operations where tool approach angles change. Unlike traditional machine vise systems that may need do-it-yourself fixes for irregularly shaped parts, the 5-axis version accommodates varying shapes and sizes without compromising hold.

It Saves Time… and Time Is Everything

That’s the best part most stores appreciate: less setup time. Because the 5-axis vise lets you cut several sides at once, you don’t waste all that time-consuming flipping, repositioning, and re-zeroing. That’s hours saved per week, sometimes per day.

And with the high-tech CNC machines more and more designed for advanced, 5-axis machining, combining them with a strong 5-axis vise is only common sense. Not only are you accomplishing more per cycle, but you’re eliminating manual adjustments that bring the whole process to a crawl.

In contrast to some older 2 jaw vise styles that have difficulty with peculiarity shaped or fragile materials, new 5-axis vises accommodate an extensive variety of materials, aluminum to titanium. Most include adjustable jaws, changeable grippers, and torque control to precisely adjust the clamping pressure.

If you’re working with expensive materials, this flexibility becomes even more crucial. A vise that adapts to different materials without damaging them is a must, and that’s another point in favor of the newer generation designs.

Integration with Modern Automation Systems

Shops today are not about expert machinists alone, they’re about intelligent automation as well. And the best news? 5-axis vises can seamlessly fit into automated stations, robotic systems, and pallet changers. You can easily mount them on horizontal, vertical, or rotary tables.

Some models even support remote adjustments, torque sensing, or status feedback. This type of integration wasn’t even a possibility with machine vise equipment a decade ago. And on high-volume production lines, this alone can deliver substantial improvements in consistency and uptime.

Compact but Mighty: The Footprint Advantage

Space is always at a premium, whether you’re in a large facility or a compact garage setup. The 5-axis vise is surprisingly space-efficient. It offers all this extra freedom for the cutting tool while occupying less space on the machine table.

This miniaturization doesn’t merely relieve spatial constraints, it also enables the use of multiple vises in parallel, amplifying throughput. In contrast to a heavier 2 jaw vise, it is evident. And in manufacturing, each inch counts.

Schunk India’s Role in Precision Workholding

When the subject of premium clamping technology and workholding solutions is raised, it’s difficult not to mention Schunk India. With Schunk being a world leader in automation and machining components, its top-notch 5-axis vises and tool holder systems are engineered to maximize efficiency and precision.

If you’re looking to invest in improving your existing setup or examining advanced solutions, it’s worth considering Schunk’s newest innovations, specifically designed for the Indian automation and machining sectors.

Are 5-Axis Vises Always the Best Choice?

Not always. Although the 5-axis vise is an amazing tool, there remain cases where the old machine vise or 2 jaw vise is more economical, particularly for less complex, flat components that don’t require tortuous machining paths.

So, assess your workflow. If your shop deals with intricate geometries, prototypes, or multi-surface parts, the upgrade is well worth it. But for straightforward, bulk part runs, sticking with basics could still be the smarter move.

Jaw Vise vs. 5-Axis Vise: What’s Worth the Upgrade?

At first glance, a 2 jaw vise might seem sufficient for most clamping needs, especially in simpler milling setups. It’s been the go-to for decades. But in the case of multi-face machining or complex geometries, the 5-axis option is difficult to overlook. The main distinction is flexibility.

Though a 2-jaw setup grips well, it hinders tool accessibility, typically demanding multiple operations to complete a piece. A 5-axis vise, however, is designed to reveal more faces on the component, cutting the number of setups significantly. That equals faster throughput, reduced scrap, and diminished operator fatigue.

If you’re still using lowly workholding tools in a complicated machining situation, you’re sacrificing efficiency. So yeah, the upgrade may cost, but the long-term payoff tends to make it a no-brainer for serious manufacturers.

Final Thoughts: Precision, Flexibility, and Productivity in One

Ultimately, it’s all about making things more efficient. The 5-axis vise doesn’t merely clamp parts, it changes the way you machine them. Whether you’re seeking improved finishes, tighter tolerances, or faster job turnarounds, this technology quietly enables them all.

Consider it your quiet productivity partner, one that requires little but delivers much in return.

So, if you’re serious about leveling up your machining operations, maybe it’s time to leave behind your old 2 jaw vise and see what the new generation of machine vise innovation can really do.