A relay is an electrical switch that uses a small electric current to control a much larger one. It works by passing current through a coil, which creates a magnetic field that moves a switch inside the device. This allows a low-power signal to safely turn on or off a high-power circuit.

Relays are essential in many areas, from home appliances and vehicles to industrial machines. They help connect sensors or small controls to powerful systems without risk to the smaller components.

Understanding how relays function reveals why they remain important even with new technology like transistors. Their ability to isolate circuits and handle large currents still makes them useful in many applications today.

How Relays Work: Core Principles

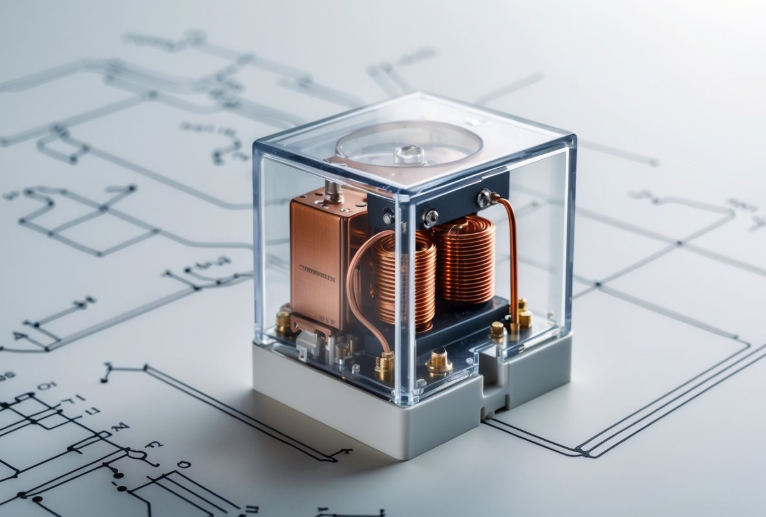

A relay is an electromechanical switch that uses a small electric current to control a larger one. Its operation depends on converting electrical energy into mechanical movement to open or close circuits. Key parts like the coil, magnetic field, armature, and spring work together to control the switch reliably.

Electromagnetic Operation

When a relay’s coil, part of the input circuit, receives current, it becomes an electromagnet. This coil is made of tightly wound wire that creates a magnetic field when electricity flows through it. The strength of this magnetic field depends on the current size.

This magnetic field attracts a movable metal armature inside the relay. The armature moves because it is pulled toward the coil when energized. This movement causes the relay contacts to either open or close, controlling the output circuit. The relay thus uses low power in the input circuit to switch a higher power output.

Role of the Magnetic Field

The magnetic field generated by the relay coil is central to its function. It creates a force strong enough to move the armature, which acts like a lever inside the switch. This force ensures the relay contacts close tightly or separate completely, depending on the relay type.

The field forms only when current flows through the coil. When the current stops, the magnetic field collapses quickly. This loss of magnetic force releases the armature. The magnetic field essentially acts as the trigger that controls the connection between circuits.

Spring and Return Mechanism

The relay includes a spring that holds the armature in place when the coil is not energized. This spring pulls the armature back to its original position, ensuring the relay contacts return to their default state.

The spring’s tension is balanced so it is strong enough to move the armature away when the magnetic field is off but weak enough to allow the magnetic force to pull the armature when energized. This system guarantees that the relay switches accurately and resets properly each time.

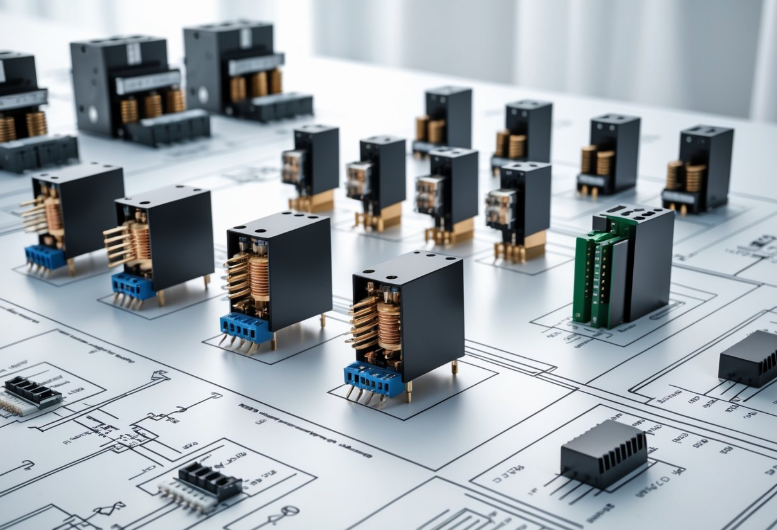

Relay Types and Switching Configurations

Relays come in different designs to handle various electrical tasks, from simple switching to protecting circuits. Each type of relay uses a specific method to open or close circuits, which affects its speed, durability, and application. Understanding these differences helps in choosing the right relay for a given situation.

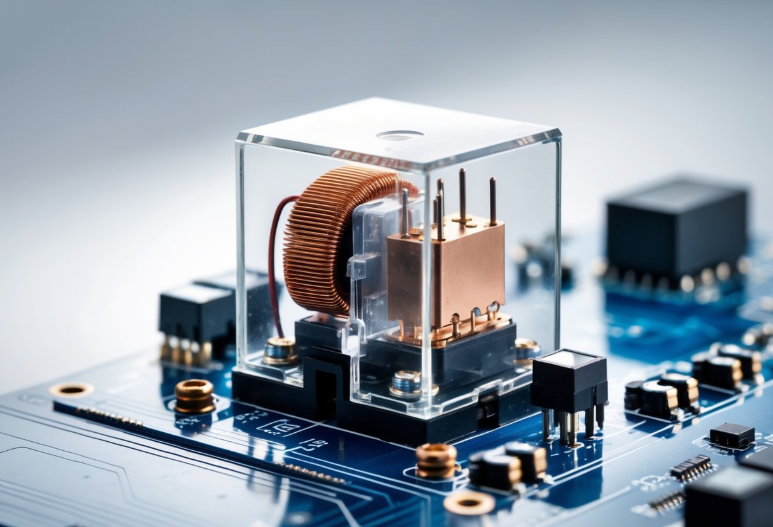

Electromechanical Relays

Electromechanical relays (EMRs) use an electromagnet to move mechanical contacts. When current flows through the coil, it creates a magnetic field that pulls a metal armature. This action closes or opens the relay switch. EMRs often have normally open (NO) or normally closed (NC) contacts. They are reliable for switching high currents and voltages in many industrial and automotive applications.

These relays are known for clear physical switching action, but they wear out over time due to moving parts. Electromechanical relays work well in circuits where switching speed is moderate and where isolation between control and power circuits is important. Reed relays are a special type of EMR using sealed contacts in a glass tube, offering fast switching and small size.

Solid-State Relays

Solid-state relays (SSRs) use semiconductor components to switch circuits without moving parts. They turn on or off by controlling internal electronic components like transistors or thyristors. SSRs provide faster switching, longer life, and quieter operation than electromechanical types.

These relays are ideal for applications needing high-frequency switching or where mechanical wear is a concern. They can switch AC or DC loads and often include built-in protection features. However, SSRs typically cost more and generate heat, so good heat dissipation is necessary to avoid damage. They provide complete electrical isolation between input control and output power circuits.

Thermal Relays

Thermal relays protect motors and equipment from overload by responding to heat. They use a bimetallic strip or other heat-sensitive element that bends as temperature rises. When the strip bends enough, it triggers a switch to open the circuit, preventing damage from excessive current.

Thermal relays are mainly used as protective relays in motor circuits. They react slower than electrical relays because their operation depends on heat buildup. These relays are simple, reliable, and do not require a power source to sense faults. However, they are less suitable for fast switching tasks and precise control applications.

Relay Contact Arrangements

Relay contacts control how electrical current flows through a relay switch. These contacts are arranged in different ways to fit various circuit needs. The terms poles and throws describe the number of separate circuits a relay can control and how those circuits are switched.

Poles and Throws Explained

A pole is a separate electrical circuit controlled by the relay. One pole means the relay controls one circuit. A relay can have multiple poles to control several circuits at once.

A throw refers to the number of different positions each pole can connect to. One throw means the pole connects to one contact, while two throws allow switching between two contacts.

For example, a Single Pole Double Throw (SPDT) relay has one pole that switches between two contacts. The throws determine if a relay’s default state is connected or open and what happens when it energizes.

SPST, SPDT, DPST, and DPDT Relays

SPST (Single Pole Single Throw) relays are the simplest type. They act as an ON/OFF switch, with one input and one output. The circuit is either connected or disconnected.

SPDT (Single Pole Double Throw) relays have one input and two outputs. The pole switches between these two outputs, allowing the circuit to connect to one or the other.

DPST (Double Pole Single Throw) relays control two separate circuits simultaneously. Both poles switch ON or OFF together but cannot switch between contacts.

DPDT (Double Pole Double Throw) relays are more flexible. They have two poles, each switching between two contacts. This allows controlling two circuits and selecting between two outputs for each pole.

| Relay Type | Poles | Throws | Function |

| SPST | 1 | 1 | Simple ON/OFF switch |

| SPDT | 1 | 2 | Switches one circuit between two outputs |

| DPST | 2 | 1 | Two circuits switched ON/OFF together |

| DPDT | 2 | 2 | Two circuits switched, each with two outputs |

These arrangements allow relays to fit different electrical control requirements in devices and machinery.

Applications of Relays in Modern Systems

Relays play a key role in controlling high-power circuits using low-power signals. They are integral to many systems, providing safety, flexibility, and efficient switching. Their applications cover areas like automated machinery, vehicles, communication networks, and lighting setups.

Industrial Automation and Motor Control

In industrial automation, relays help control motors and other heavy machinery. They allow small control signals to switch large electrical loads safely. This is important because direct control of motors by manual switches would require bulky, expensive devices.

Relays isolate control circuits from power circuits. This protects sensitive automation systems from high voltages. Time delay relays are often used to sequence machines or prevent overload by delaying motor starts or stops.

Electromechanical relays remain popular in motor control due to their ability to carry large currents. However, solid-state relays offer faster switching and longer life where noise or wear is a concern. Both types support complex automation processes reliably.

Automotive and Transportation Systems

Relays are essential in automotive systems to manage devices with high current demands. For example, headlights, horns, and electric windows use relays to switch heavy loads from low-current dashboard controls.

They provide electrical isolation that protects vehicle electronics. Relays enable control of various safety and comfort features without running large current through switches the driver operates directly.

Automotive relays must be durable to withstand vibrations and temperature changes. Solid-state and hybrid relays are increasingly popular for reliability. Relays also help in battery management and electric motor control in modern vehicles.

Telecommunications and Electronic Circuits

Relays in telecommunications route signals and control circuits within exchanges and networking equipment. They allow low-power control signals to switch complex high-frequency or high-voltage circuits safely.

In electronic circuits, relays can isolate sensitive amplifiers and transistors from damaging interference. Reed relays, with their sealed design and fast response, are common in test equipment and precision devices because they are quiet and reliable.

Relays support the switching of communication lines and ensure fail-safe operation. They are key in automation of signal paths without manual intervention, improving efficiency and network reliability.

Lighting and Power Distribution

Relays make lighting control more flexible and efficient by switching large currents in lighting circuits from low-power controls like sensors or timers. This helps save energy and protect control switches.

In power distribution, relays detect faults and isolate problem areas automatically. They serve as protective devices to prevent damage to wiring and equipment, improving system safety.

Lighting time delay relays allow lights to stay on briefly after a switch is turned off, aiding safety. Relays also enable remote control of lighting systems in homes and commercial buildings, supporting the rise of smart home automation.

Premium electrical and automation equipment

When it comes to electrical and automation equipment, quality is essential. Premium products provide enhanced safety, reliability, and performance. They help prevent hazards that can arise from using lower-quality devices.

Key Features of Premium Equipment:

- Safety Standards: Premium equipment often meets or exceeds international safety standards, ensuring it operates safely and efficiently.

- Durability: Quality materials and robust construction lead to longer lifespans, reducing the need for frequent replacements.

- Performance: High-end devices generally offer better efficiency, which can lead to lower energy costs and improved output.

Investing in premium equipment can significantly reduce risks. For instance, safety features are built-in to prevent electrical faults. Additionally, reputable brands provide proper certifications and guidelines, assuring users of their safety.

Examples of Premium Equipment Providers:

- Gabby Electric: Known for its extensive range of electrical products, Gabby Electric emphasizes quality and safety. Their offerings include automation solutions designed for various industries.

Benefits of Choosing Premium Brands:

- Peace of mind knowing safety is prioritized.

- Better support and warranty options.

- Access to the latest technology and innovations.

Purchasing premium electrical and automation equipment can enhance safety and performance while minimizing the risks associated with lower-quality products.