The term box build assembly refers to the process of integrating printed circuit boards (PCBs), electronic components, wiring, and enclosures into a complete, functional product. This crucial step in electronics manufacturing transforms separate assemblies into ready-to-use systems that can be deployed directly in end-user environments.

Whether it’s an industrial controller, communication device, or medical instrument, box build assembly ensures that every element works together seamlessly. It’s the bridge between PCB-level manufacturing and final product delivery — a process that demands precision, efficiency, and in-depth technical expertise.

What Is Box Build Assembly?

Box build assembly, also known as systems integration or full product assembly, involves more than just connecting wires and mounting PCBs. It is a comprehensive process that includes:

- Installing printed circuit boards into enclosures

- Assembling submodules and cable harnesses

- Integrating mechanical parts such as brackets, panels, and displays

- Programming firmware or software

- Conducting functional and quality assurance testing

The objective is to produce a completely integrated system that is tested, certified, and ready for shipment. For many companies, outsourcing box build assembly to experienced manufacturers is a cost-effective way to streamline production while maintaining high quality and consistency.

The Process of Box Build Assembly

- Design Review and Planning

Before the assembly process begins, manufacturers conduct a detailed review of the client’s designs and specifications. This includes understanding the system’s mechanical, electrical, and thermal requirements. Engineering teams create a plan that outlines materials, components, and assembly procedures.

- Material Procurement and Component Preparation

In a box build assembly, material selection is vital. The manufacturer sources electronic components, cables, connectors, and mechanical parts from reliable suppliers. In some cases, clients provide specific materials, while others rely on the assembler’s procurement expertise.

- Sub-Assembly Manufacturing

This stage involves building and testing individual subassemblies, such as PCB modules, cable harnesses, or control panels. Each subassembly undergoes inspection to ensure functionality before integration.

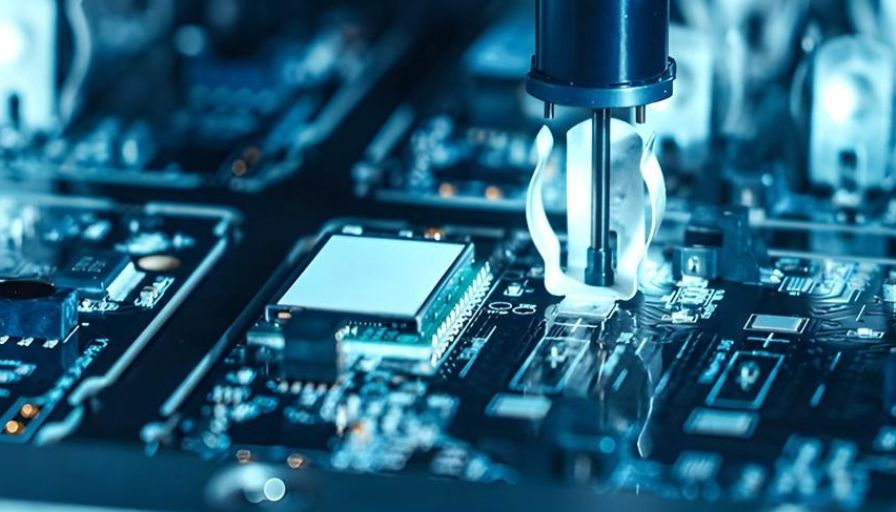

- Mechanical Assembly and Integration

All subassemblies are installed into the product’s enclosure. This includes attaching circuit boards, connecting wiring, securing panels, and installing hardware such as switches, fans, or displays. The layout must be precise to prevent interference, overheating, or component misalignment.

- Firmware and Software Installation

If the system requires programming, technicians load firmware or software during this stage. This step transforms the hardware into a fully operational electronic product.

- Testing and Quality Control

Every assembled product undergoes rigorous testing to verify performance and safety. Common tests include continuity, insulation resistance, functional, and environmental tests. Quality assurance ensures that the box build assembly meets all regulatory and industry standards.

- Packaging and Logistics

Finally, completed units are cleaned, packaged, and labeled for shipment. Some manufacturers offer custom packaging to protect sensitive electronics during transport or to meet branding requirements.

Advantages of Box Build Assembly

- Streamlined Manufacturing Process

Outsourcing box build assembly consolidates multiple production steps under one supplier, reducing coordination time and logistics costs. It also minimizes the risk of communication errors between different vendors.

- Improved Quality and Reliability

Professional manufacturers use advanced tools and quality management systems to ensure high assembly accuracy. Every product undergoes multiple inspections, ensuring durability and consistency.

- Faster Time-to-Market

A well-organised box build assembly line accelerates production cycles. By integrating PCB assembly, cable harnessing, and enclosure installation in one process, companies can launch products faster.

- Cost Efficiency

Combining different production stages into a single service reduces overall costs related to transportation, labour, and inventory management. Manufacturers can also source materials in bulk, lowering procurement expenses.

- Customisation and Flexibility

Each box build assembly can be tailored according to specific client requirements. Whether the design calls for unique enclosures, connectors, or branding, manufacturers can adapt to varying project needs.

Applications of Box Build Assembly

Box build assembly plays a key role in multiple industries where fully integrated systems are required.

- Industrial Automation

In factories and process plants, box builds are used for control systems, PLC units, and machine interface panels. They are built to withstand harsh environments and continuous operation.

- Telecommunications

Telecom equipment such as network routers, amplifiers, and signal converters rely on precise box build assembly to maintain stable data flow and communication reliability.

- Medical Electronics

In the healthcare sector, box build assemblies are used in diagnostic equipment, imaging systems, and monitoring devices. High precision and safety compliance are essential in this field.

- Consumer Electronics

Household and personal electronics like smart home devices, wearables, and entertainment systems also benefit from compact and reliable box build integration.

- Automotive and Transportation

Vehicle control modules, infotainment systems, and EV charging units use box build assembly to combine electronics into rugged, vibration-resistant enclosures.

Challenges in Box Build Assembly

While box build assembly offers multiple benefits, it also presents challenges that require expertise and planning. Some key challenges include:

- Managing a wide range of component types and sizes

- Ensuring EMI (Electromagnetic Interference) shielding

- Maintaining thermal balance within the enclosure

- Meeting safety and certification standards such as UL, CE, or ISO

Experienced manufacturers address these challenges through simulation, design optimisation, and strict process control.

The Future of Box Build Assembly

As electronic systems grow more advanced, the box build assembly process is evolving too. Industry trends include:

- Automation and robotics for precise assembly and testing

- IoT-enabled systems that require more compact and intelligent integration

- Green manufacturing using lead-free soldering and recyclable materials

- Digital twins for virtual testing before physical assembly

Manufacturers that adopt these innovations are improving efficiency, sustainability, and product performance.

Conclusion: Partner with Experts Offering One Stop PCB Assembly Services

The box build assembly process is essential for bringing complex electronic systems to life. From industrial automation to medical and automotive applications, it ensures functionality, reliability, and ease of deployment.

To achieve superior quality and efficient integration, it’s vital to collaborate with a trusted manufacturer that offers one stop PCB assembly services. A reliable partner can manage everything — from PCB production and wiring to enclosure integration and testing — all under one roof. This streamlined approach not only saves time and cost but also ensures consistent performance and quality.

By choosing an experienced provider offering one stop PCB assembly services, your business gains the assurance of high-quality craftsmanship, timely delivery, and complete system reliability for your next-generation electronic products.