Safeguarding distribution networks is critical to ensure both operational efficiency and personnel safety in industrial and commercial electrical systems. One of the most essential devices in this regard is the feeder protection relay. These electrical instruments are designed to detect faults, monitor current flows, and isolate problematic sections of a network before they escalate into serious damage.

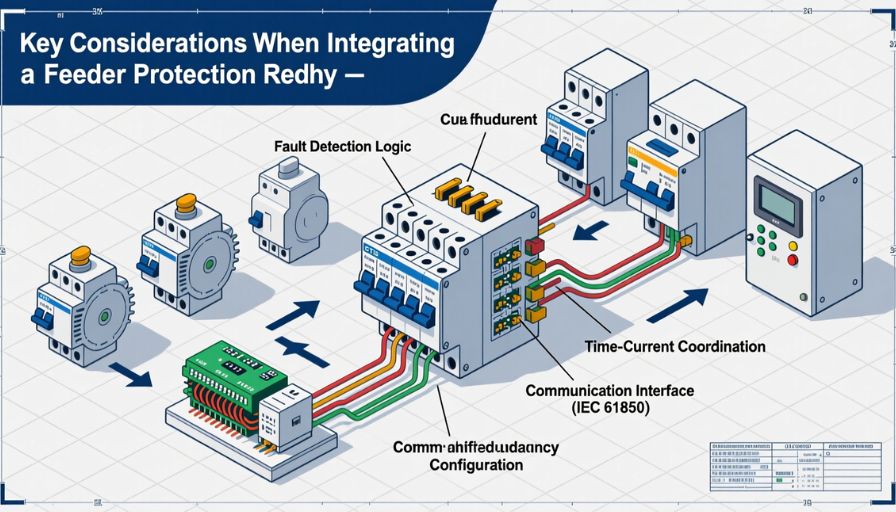

As industries adopt more complex electrical setups, understanding the key considerations when integrating a feeder protection relay becomes increasingly important.

Understanding Feeder Protection Relays

A feeder protection relay is an intelligent device that monitors electrical feeders in a distribution system. Its primary function is to detect abnormal conditions such as overloads, short circuits, or phase imbalances and trigger circuit isolation mechanisms to prevent equipment damage. Modern relays often incorporate digital technology, enabling accurate fault detection and real-time monitoring.

Selecting the right relay depends on multiple factors, including the type of feeder, load characteristics, and the criticality of the system. Employing a relay that matches the operational requirements ensures optimal protection without unnecessary interruptions to the electrical network.

Evaluating System Requirements

Before deploying a feeder protection relay, it is essential to conduct a thorough assessment of the electrical system. Factors to consider include feeder length, load profile, and system voltage. Longer feeders may require relays with advanced communication capabilities, while feeders with variable loads may benefit from adaptive relay settings.

Additionally, it is important to assess the coordination of protection across the network. Integrating a relay that is compatible with existing devices and control schemes ensures selective tripping, preventing widespread outages and minimizing operational disruption.

Integration with Existing Equipment

Modern electrical systems often comprise a mix of legacy and new devices. A feeder protection relay must be compatible with both to function effectively. Integration involves ensuring that the relay can communicate with other protective devices, switchgear, and monitoring systems.

Employing relays with standardized communication protocols simplifies integration and enhances overall system reliability. Incorporating these instruments into a centralized monitoring platform allows operators to track performance, detect anomalies, and respond promptly to any issues.

Setting Correct Protection Parameters

Proper configuration is critical when deploying a feeder protection relay. Key parameters include current settings, time delays, and sensitivity thresholds. Setting these correctly ensures the relay responds accurately to genuine faults without triggering unnecessary interruptions.

Employing adaptive or programmable relays provides flexibility for industries with changing load conditions. These relays can adjust settings dynamically based on real-time monitoring, improving protection effectiveness while reducing the likelihood of false trips.

Ensuring Regular Maintenance and Testing

Once integrated, a feeder protection relay requires periodic maintenance and testing. Routine checks verify that the device continues to operate within specified parameters and can reliably detect faults.

Testing should include simulations of overload and short-circuit conditions, as well as validation of communication with other system devices. Proper maintenance ensures the longevity of the relay and the overall safety of the electrical network.

Incorporating Advanced Features

Modern feeder protection relays offer a range of advanced features that enhance safety and operational efficiency. Some devices incorporate fault recording, event logging, and predictive analytics, allowing operators to identify potential issues before they escalate.

Additionally, certain relays can interface with remote monitoring systems, enabling real-time supervision and quicker response times. Incorporating these capabilities into industrial electrical systems improves both reliability and resilience.

Partner with Reputable Energy Brands

Integrating a feeder protection relay is most effective when done in collaboration with trusted energy partners. Reputable brands offer reliable devices that meet strict safety and performance standards, ensuring that industrial systems remain protected.

These partners also provide technical expertise for installation, configuration, and ongoing maintenance, helping organizations maximize the performance and longevity of their electrical instruments. By working with established providers, businesses gain access to high-quality equipment, professional support, and the assurance that their distribution networks are safeguarded against faults and operational risks.