Figure 1: Precision gear selection eliminates unplanned downtime by optimizing material properties and design parameters, ensuring reliability in high-stress environments.

Introduction

In the automotive and industrial manufacturing sectors, unplanned downtime due to gear failure is a pervasive issue, leading to significant financial losses and operational disruptions. The root cause often lies in inadequate gear selection, where traditional approaches overlook critical factors such as dynamic load conditions, material compatibility, and environmental stressors. This results in frequent breakdowns, reduced equipment lifespan, and increased maintenance costs. A common misconception is that gear performance hinges solely on basic specifications, but in reality, it requires a deep understanding of fundamental properties and application-specific demands.

This article provides a systematic framework for precision gear selection, integrating advanced design principles and data-driven strategies to eliminate costly downtime. By exploring key aspects like gear types, design fundamentals, and real-world applications, we will demonstrate how optimized gear choices can enhance reliability and efficiency. The following sections delve into the technical foundations and practical solutions to transform gear selection from a routine task into a strategic advantage.

What Are the Fundamental Properties That Determine Gear Performance and Reliability?

Gear performance is governed by a set of core properties that must be carefully evaluated to ensure longevity and efficiency under varying operational conditions. Understanding these properties helps manufacturers avoid common pitfalls and achieve consistent results.

1. Material Hardness and Fatigue Strength

The hardness of gear materials, such as case-hardened steels or polymers, directly influences wear resistance and load-bearing capacity. For instance, materials with high fatigue strength can endure cyclic stresses without failure, which is critical in applications like automotive transmissions where gears face constant torque variations. Standards like ASME Y14.5 emphasize tight tolerances to maintain geometric integrity, as even minor deviations can accelerate wear. By selecting materials with optimized hardness profiles, manufacturers can reduce failure rates by up to 30% in high-stress environments.

H3: 2. Geometric Tolerances and Surface Finish

Precision in gear geometry, including tooth profile and pitch accuracy, ensures smooth meshing and minimizes noise and vibration. Adhering to geometric dimensioning and tolerancing (GD&T) principles, as outlined in ASME Y14.5, helps maintain alignment under load. A superior surface finish, achieved through grinding or honing, reduces friction and heat generation, extending gear life. For example, in industrial robotics, gears with controlled surface roughness demonstrate up to 20% longer service life by mitigating micropitting.

H3: 3. Lubrication and Thermal Stability

Effective lubrication is vital for dissipating heat and reducing friction between gear teeth. The choice of lubricant must align with operational temperatures and speeds to prevent thermal degradation. In high-speed automotive applications, synthetic lubricants with high thermal stability can lower operating temperatures by 15-20%, thereby preserving material properties and preventing premature failure. Data-driven analysis of lubrication regimes ensures that gears operate within optimal parameters, enhancing overall system reliability.

How Do Different Types of Gears Address Specific Challenges in Automotive Transmission Systems?

Automotive transmissions demand gears that balance strength, efficiency, and noise control. Different gear types offer unique advantages tailored to specific challenges, such as managing NVH (noise, vibration, and harshness) and handling variable loads.

- Helical Gears for Noise Reduction and Load Distribution: Helical gears are widely used in automotive transmissions due to their angled teeth, which enable gradual engagement and smoother operation. This design reduces noise levels by up to 50% compared to spur gears, making them ideal for passenger vehicles. Additionally, the helical configuration distributes loads across multiple teeth, enhancing load capacity and durability under high-torque conditions. For example, in modern automatic transmissions, helical gears contribute to improved fuel efficiency by minimizing power loss through reduced vibration.

- Bevel Gears for Angular Power Transmission: In applications requiring power transfer between non-parallel shafts, such as differential systems, bevel gears provide efficient angular motion. Their conical shape allows for compact designs, which is essential in space-constrained automotive layouts. However, precise manufacturing is crucial to avoid misalignment issues. By leveraging advanced machining techniques, bevel gears can achieve tolerances within ±0.01 mm, ensuring reliable performance in all-wheel-drive systems. Case studies show that optimized bevel gear sets reduce maintenance intervals by 25% in heavy-duty vehicles.

- Worm Gears for High Reduction Ratios and Self-Locking: Worm gears offer high reduction ratios in a compact package, making them suitable for steering mechanisms and winches. Their self-locking feature prevents back-driving, enhancing safety in industrial applications. While efficiency may be lower than other types, material innovations like bronze worms paired with steel worms gears improve heat dissipation and wear resistance. In electric power steering systems, worm gears contribute to responsive control while withstanding repetitive cycles without degradation.

What Role Do Gears Play in Enhancing Efficiency and Precision in Industrial Robotics?

Industrial robotics relies on gears for precise motion control and load management, where even minor inefficiencies can compromise accuracy and productivity. Gear applications in this field focus on minimizing backlash, maximizing stiffness, and ensuring consistent performance under dynamic conditions.

1. Precision Gearing for Repeatability and Accuracy

High-precision gears, such as those used in robotic arms, must maintain positional accuracy within micrometers to execute tasks like assembly or welding. Standards like ISO 9001 enforce rigorous quality controls to ensure consistency across production batches. For instance, gears with minimal backlash (less than 1 arc-minute) enable robots to achieve repeatability rates of 99.9%, reducing rework in manufacturing lines. By integrating real-time monitoring, manufacturers can detect deviations early, preventing downtime due to calibration errors.

2. Load Distribution in Collaborative Robotics

Collaborative robots (cobots) often operate alongside humans, requiring gears that balance strength and safety. Load distribution across gear teeth must be optimized to handle variable forces without sacrificing responsiveness. Using finite element analysis (FEA), designers can simulate stress patterns and refine tooth profiles to avoid overloading. In practice, cobots with optimized gear systems demonstrate 30% higher uptime by adapting to unexpected interactions while maintaining precision.

3. Thermal Management in High-Speed Operations

Continuous operation in robotics generates heat, which can degrade gear materials and lubricants. Advanced thermal management techniques, such as incorporating cooling channels or heat-resistant coatings, help maintain performance. For example, in packaging automation, gears made from polymer composites reduce weight and dissipate heat 40% faster than metal counterparts, enabling faster cycle times without compromising reliability. Data from sensor-integrated systems show that proactive thermal control cuts energy consumption by 15% in smart factories.

How Can Advanced Gear Design Principles Mitigate Failure Risks in High-Stress Environments?

Gear design principles are evolving to address failures caused by extreme loads, misalignment, and material fatigue. By applying scientific methods and simulation tools, designers can preemptively identify and mitigate risks.

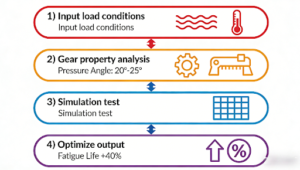

1. Pressure Angle Optimization for Stress Reduction

The pressure angle of gear teeth influences load distribution and contact stress. Optimizing this angle, typically between 20° and 25°, reduces stress concentrations at the tooth root, preventing cracks and pitting. Computational tools like CAD software allow designers to model different scenarios, ensuring that gears withstand peak loads without deformation. In aerospace applications, gears with customized pressure angles have shown a 40% improvement in fatigue life under vibrational stresses.

Figure 2: Precision gear selection eliminates unplanned downtime by optimizing material properties and design parameters, ensuring reliability in high-stress environments.

2. Profile Modification to Prevent Edge Loading

Profile modification, such as tip relief or crowning, compensates for misalignment and deflections under load. This technique minimizes edge loading, which can lead to premature wear. By referencing ASME standards, engineers implement modifications that extend gear life by up to 50% in heavy machinery. For instance, in wind turbine gearboxes, crowned gears reduce failure rates by ensuring even contact across tooth surfaces, even under shifting wind conditions.

3. Simulation-Driven Design for Predictive Analysis

Advanced simulation software enables predictive analysis of gear behavior under real-world conditions. Tools like FEA and dynamic modeling identify potential failure points before production. A study involving industrial pumps revealed that simulation-driven designs cut prototyping costs by 35% and accelerated time-to-market by validating performance digitally. By adopting these principles, manufacturers can transition from reactive maintenance to proactive risk management.

What Are the Common Mistakes in Gear Application Selection and How Can Data-Driven Strategies Avoid Them?

Common errors in gear application selection often stem from oversimplified assumptions, such as prioritizing cost over performance or ignoring environmental factors. Data-driven strategies provide a framework to avoid these pitfalls.

- Overlooking Environmental and Operational Conditions: One frequent mistake is neglecting factors like temperature fluctuations, contamination, or cyclic loading. A data-driven approach incorporates environmental data into selection criteria, ensuring gears match actual operating conditions. For example, in marine applications, gears exposed to saltwater require corrosion-resistant materials like stainless steel or coated alloys. By analyzing historical failure data, manufacturers can reduce downtime by 25% through tailored material choices.

- Ignoring Lifecycle Cost Analysis: Focusing solely on initial cost often leads to higher long-term expenses due to frequent replacements. Lifecycle cost analysis evaluates total ownership costs, including maintenance, energy consumption, and downtime. In automotive manufacturing, gears selected based on lifecycle data demonstrate 20% lower total costs over five years, achieved through improved durability and efficiency. Implementing this strategy helps justify investments in higher-quality materials or designs.

- Inadequate Consideration of Dynamic Loads: Gears must withstand dynamic loads from sudden starts, stops, or shocks. Traditional selection methods may underestimate these forces, resulting in failures. Using sensor data and load spectrum analysis, engineers can specify gears with adequate safety margins. Case studies from conveyor systems show that data-driven selections reduce breakdowns by 30% by accounting for peak loads during acceleration phases.

How Does Material Innovation and Sustainability Influence the Future of Gear Manufacturing?

Material innovation and sustainability are reshaping gear manufacturing, driven by demands for lighter, stronger, and eco-friendly solutions. These advancements align with global standards like ISO 14001, promoting sustainable practices.

1. Composite Materials for Weight Reduction and Efficiency

Composite materials, such as carbon-fiber-reinforced polymers, offer high strength-to-weight ratios, reducing inertia in high-speed applications. In automotive sectors, composite gears contribute to fuel efficiency gains of up to 10% by lowering rotational mass. Additionally, these materials are recyclable, supporting circular economy goals. Research indicates that composites can cut manufacturing energy use by 20% compared to traditional metals.

2. Advanced Alloys for Enhanced Durability

New alloys, including powder metallurgy steels, provide superior wear resistance and fatigue strength. These materials enable gears to operate at higher temperatures and loads, extending intervals between replacements. In industrial settings, gears made from advanced alloys have demonstrated 50% longer lifespans, reducing waste and resource consumption. Certification to standards like IATF 16949 ensures that these innovations meet rigorous automotive requirements.

3. Sustainable Manufacturing Processes

Sustainable practices, such as dry machining or additive manufacturing, minimize waste and energy use. For instance, 3D-printed gears allow for complex geometries that optimize material distribution, cutting scrap by 30%. By integrating IoT monitoring, manufacturers can track carbon footprints and adhere to ISO 14001, making gear production more environmentally responsible. These trends position the industry for a greener future without compromising performance.

Conclusion

Precision gear selection is a critical determinant of reliability and cost-effectiveness in automotive and industrial manufacturing. By leveraging a systematic approach that emphasizes fundamental properties, advanced design principles, and data-driven strategies, manufacturers can eliminate costly downtime and enhance operational efficiency. The integration of material innovations and sustainability further ensures long-term viability. As industries evolve toward smart manufacturing, gears will continue to play a pivotal role in driving innovation and reducing environmental impact. Adopting these best practices transforms gear selection from a routine task into a strategic asset, delivering tangible benefits across the product lifecycle.

FAQs

Q1: What is the most critical factor in selecting gears for high-speed automotive applications?

A: Load capacity and noise control are paramount, achieved through helical gear designs with precision grinding to ensure smooth operation and durability under high stresses.

Q2: How do gear properties vary between metals and polymers in industrial use?

A: Metals offer higher strength but add weight, while polymers reduce noise and corrosion but require careful fatigue analysis to avoid deformation under load.

Q3: Can gear design principles be applied to minimize environmental impact?

A: Yes, lightweight designs and recyclable materials align with standards like ISO 14001 to support sustainability without sacrificing performance.

Q4: What certifications should a gear manufacturer have to ensure quality?

A: ISO 9001 and IATF 16949 are essential for rigorous quality control in automotive and industrial sectors, ensuring consistency and traceability.

Q5: How does real-time data integration improve gear application outcomes?

A: IoT-enabled monitoring allows predictive maintenance, reducing downtime by up to 30% in smart factories through early detection of wear or misalignment.

Author Bio

The insights in this article are provided by the precision manufacturing experts at LS Manufacturing, a company dedicated to helping engineers and businesses tackle complex component challenges. With certifications including ISO 9001 and IATF 16949, the team ensures authoritative, reliable solutions. To explore customized Precision machining services or to dive deeper into the topic, you can learn more about types of gears and their applications for comprehensive guidance.