In the world of metal cutting, technology is changing fast. One of the newest and most useful methods is bevel laser cutting. This process is now being used more and more in industries like construction, shipbuilding, and metal fabrication. Why? Because it offers many big advantages over old, traditional cutting methods.

Let’s take a simple look at how bevel laser cutting works and why it is better for modern businesses.

What Is Bevel Laser Cutting?

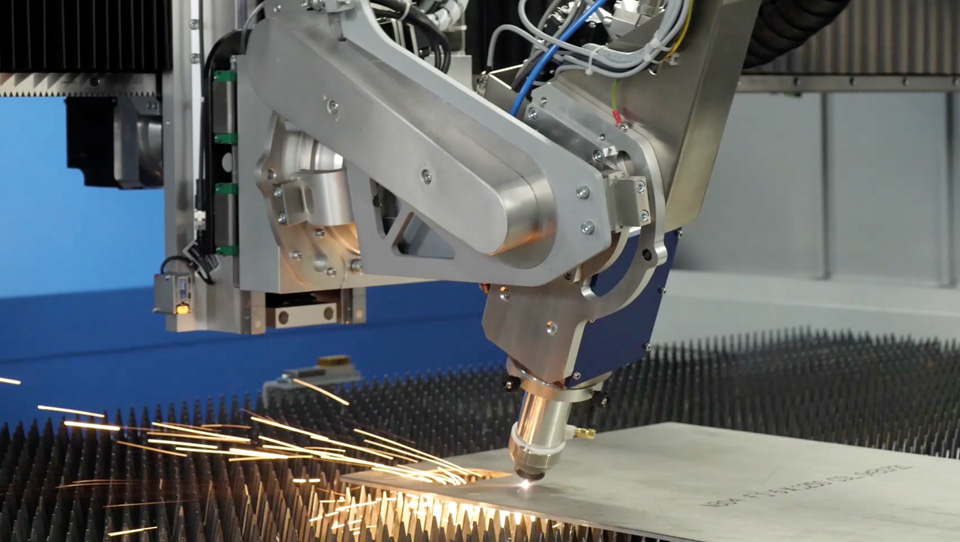

Bevel -laser slicing is a unique manner to cut metal. Unlike ordinary laser cuttings, which cut straight cuts, laser cutting of slit can be reduced from a perspective. This special segment is referred to as “Bevel”. It is beneficial when making parts that need to fit together closely.

This approach is used when you need clean, angular edges for welding or the manufacture of strong elements. It facilitates store time and conveys higher effects.

A great example of this technology is the DOWELL bevel laser cutting machine. This machine offers smart cutting with high speed and accuracy.

How Is It Different from Traditional Cutting?

Traditional cutting methods like plasma cutting, waterjet cutting, or manual cutting tools can also cut metal. But these older tools have many problems:

- Less accurate

- Slower

- More waste material

- Rough edges

- Higher chance of mistakes

In contrast, bevel laser cutting is fast, clean, and very precise. Like this is why many factories and workshops are switching to laser technology.

1. Better Cutting Precision

One of the top benefits of bevel laser cutting is precision. The laser beam is controlled by computer software. And this means the machine cuts exactly where it should.

With a DOWELL bevel laser cutting machine, you can create sharp, clean bevels every time. Even the smallest details come out perfect—no more rough edges or mistakes.

2. Saves Time and Labor

Traditional cutting takes time. You often need more than one machine or extra workers to clean or finish the parts. But with bevel laser cutting, the machine does everything at once.

It cuts and bevels in one step. You don’t need to move the part to another tool. This saves time, labor, and money.

3. Clean and Smooth Edges

Laser cutting gives smooth and shiny edges. There’s no need to grind or polish the part later. Then this makes the whole process faster and cleaner.

When you use bevel laser cutting, you get ready-to-use parts with no extra work. This is a big plus for companies that need fast delivery or make many parts daily.

4. Less Material Waste

Old cutting tools often waste a lot of material. But lasers are more focused and thin. They only cut where needed. This means you use less metal and save more money.

Also, machines like the DOWELL bevel laser cutting machine are designed to cut smartly. They help reduce scrap and make the most of every sheet or metal plate.

5. Perfect for Welding Preparation

Bevel edges are very helpful for welding. They make the weld joints stronger and more aesthetically pleasing. Traditional beveling often takes a long time and needs skilled workers.

But with laser cutting, the bevel is automated and very accurate. This means perfect angles for fast and strong welding. It also helps meet quality standards in industries like aerospace and automotive.

6. Supports Complex Designs

Many modern products need complex shapes and cuts. Laser bevel cutting makes it possible to cut curves, corners, and even tiny holes with ease.

If your business makes custom metal parts, you will love this feature. You can easily change the design using a computer. Machines like those from dwcnclaser.com help bring new ideas to life quickly.

7. Cost-Effective in the Long Run

While laser cutting machines may seem expensive at first, they save money over time. You spend less on labor, and less on repairs, and less on materials.

You also finish more projects in less time. For businesses that work on large or urgent orders, this is a huge advantage. Using a machine like the DOWELL bevel laser cutting machine helps companies grow faster.

8. Safe and Easy to Use

Modern laser machines are made with safety in mind. They come with automatic systems, covers, and emergency stops. Workers don’t need to be close to the laser while it’s cutting.

The software is also easy to use. You don’t need a lot of training to run it. Sites like dwcnclaser .com

offer user guides and support for their machines, too.

Why More Companies Are Choosing Bevel Laser Cutting

Today’s market calls for velocity, nice, and price control. Bevel -laser cutting offers you all three. This is why metallic work, car, creation, and aerospace groups switch to smart lasers from the vintage equipment.

With higher edges, sharp outputs, and little waste, Dowell Bevel enables laser cutting machine corporations to stand out in front of the competition.

Conclusion

Simply positioned, sloping laser cutting is higher than conventional cutting in many ways. It is speedy, easy, and accurate. This allows companies to save time and money, whilst the quality of work is also improved.

If your enterprise works with steel, it’s time to consider upgrading your equipment. Go to dwcnclaser.com to learn more about the great machines available, such as the Dowell Bevel Laser Cutting Machine. This may be a smart option that leads your production to the next level.