The Electronic Manufacturing Process is the foundation of modern technology, shaping everything from smartphones and medical devices to automotive systems and industrial machinery. This process involves transforming raw electronic components into fully functional products through a series of precise and highly controlled steps.

In today’s fast-paced world, businesses rely on efficient and reliable manufacturing methods to maintain quality, reduce costs, and bring products to market faster. Understanding how the electronic manufacturing process works helps engineers, designers, and companies optimise every stage — from concept to completion.

What Is the Electronic Manufacturing Process?

The Electronic Manufacturing Process refers to the comprehensive workflow involved in designing, fabricating, assembling, testing, and delivering electronic products. It integrates multiple disciplines, including electrical engineering, material science, and production management, to ensure that every product functions according to its intended purpose.

This process is typically handled by specialised manufacturers equipped with advanced machinery and automation systems. Their expertise ensures precision in soldering, assembly, and testing — essential factors for high-performance electronic devices.

Key Stages of the Electronic Manufacturing Process

- Design and Prototyping

Every successful electronic product starts with a robust design. Engineers create schematics and PCB (Printed Circuit Board) layouts using CAD software to determine how components will connect and function. During this phase, the focus is on efficiency, size reduction, and manufacturability.

Prototyping follows the design stage, allowing engineers to create small batches of the product for functional testing. This step helps identify potential design flaws before large-scale production begins.

- Component Procurement

Once the prototype is finalised, the next step is sourcing components. Manufacturers acquire resistors, capacitors, ICs, connectors, and other electronic parts from trusted suppliers. Quality assurance at this stage is crucial, as counterfeit or low-quality components can lead to product failures.

Many manufacturers maintain direct relationships with global distributors to ensure the authenticity and traceability of each part.

- PCB Fabrication

At the heart of the Electronic Manufacturing Process is the PCB fabrication phase. This involves creating the printed circuit board that connects all electronic components. The fabrication process includes:

- Etching: Removing excess copper to define circuit paths.

- Drilling: Creating holes for through-hole components.

- Lamination: Combining multiple layers for complex designs.

- Surface Finishing: Applying coatings such as HASL or ENIG to enhance solderability.

The PCB must meet tight tolerances to ensure proper electrical performance and reliability.

- PCB Assembly

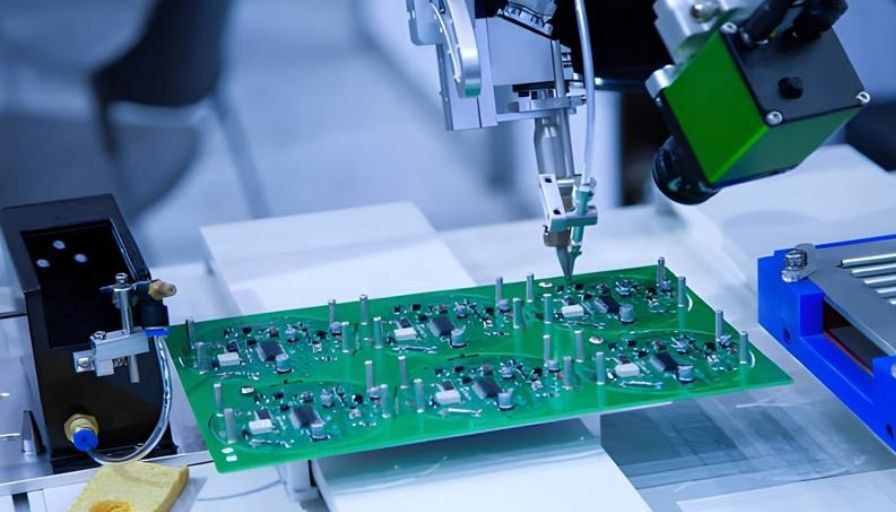

In this stage, components are mounted onto the fabricated PCB using Surface Mount Technology (SMT) or Through-Hole Technology (THT).

- SMT Assembly: Components are placed directly onto the surface of the PCB, ideal for compact and high-density designs.

- Through-Hole Assembly: Leads are inserted through drilled holes and soldered, providing stronger mechanical support for larger parts.

Automated pick-and-place machines and reflow ovens ensure accuracy and consistency during the assembly process.

- Soldering Process

After component placement, the soldering process secures the electrical connections. Reflow soldering is used for SMT components, where boards are heated to melt the solder paste and form strong joints. For through-hole parts, wave soldering may be applied.

Proper soldering techniques are essential for durability and to avoid issues like cold joints or bridging.

- Inspection and Testing

Testing is a critical phase of the Electronic Manufacturing Process, ensuring that each product performs correctly before shipment. Common testing methods include:

- Automated Optical Inspection (AOI): Checks for solder defects and missing components.

- In-Circuit Testing (ICT): Verifies circuit functionality.

- Functional Testing: Ensures the product meets operational requirements under real-world conditions.

Advanced manufacturers may also use X-ray inspection to detect hidden defects, especially in BGA (Ball Grid Array) assemblies.

- Final Assembly and Packaging

After testing, the boards are cleaned, conformal coated (if required), and assembled into their final product enclosures. Proper packaging prevents damage during transportation and ensures products reach customers in perfect condition.

Importance of Quality Control in the Electronic Manufacturing Process

Maintaining strict quality control throughout the Electronic Manufacturing Process is vital. Even minor defects in assembly or testing can lead to costly recalls or failures in the field. Reputable manufacturers follow international standards such as ISO 9001, IPC-A-610, and RoHS compliance to guarantee safety and performance.

Quality assurance is integrated into every step — from material inspection and component verification to process monitoring and final product testing.

Advantages of an Efficient Electronic Manufacturing Process

- Cost-Effective Production

Streamlining processes and automating key stages reduce labour costs and material waste. This results in more affordable products without compromising quality.

- Faster Time-to-Market

With advanced design tools and automated production lines, manufacturers can complete projects quickly, helping businesses meet tight deadlines and gain a competitive edge.

- Enhanced Product Reliability

Precision manufacturing and rigorous testing ensure that each electronic device performs consistently, even in demanding environments such as automotive or aerospace applications.

- Scalability

The process allows smooth transition from prototype development to full-scale mass production, accommodating both small startups and large industrial clients.

- Innovation and Flexibility

Modern electronic manufacturing supports complex designs, including multilayer PCBs, flexible circuits, and mixed-technology assemblies. This flexibility promotes innovation and adapts easily to emerging technologies.

Trends Shaping the Future of Electronic Manufacturing

The Electronic Manufacturing Process continues to evolve with advancements in technology. Some key trends include:

- Automation and Robotics: Enhancing precision and production speed.

- AI-Driven Quality Control: Detecting errors automatically using machine learning.

- Miniaturisation: Supporting smaller, more powerful devices.

- Sustainable Manufacturing: Reducing waste and energy consumption.

- IoT Integration: Enabling real-time monitoring of production lines.

These innovations are setting new benchmarks for efficiency and quality across the global electronics industry.

Conclusion: Partner with Experts for Reliable Electronic Manufacturing

The Electronic Manufacturing Process is a sophisticated and multi-layered journey that transforms designs into functional, high-performance products. From concept development to final assembly, every step demands precision, experience, and advanced technology.

Partnering with an experienced provider of Electronics Manufacturing Services ensures that your products meet the highest industry standards. With access to modern facilities, skilled engineers, and a commitment to quality, such partners can handle everything from prototype design to mass production — allowing your business to focus on innovation while they manage the manufacturing complexities.

A trusted partner in Electronics Manufacturing Services guarantees not only efficiency but also the long-term success of your electronic products in a competitive global market.