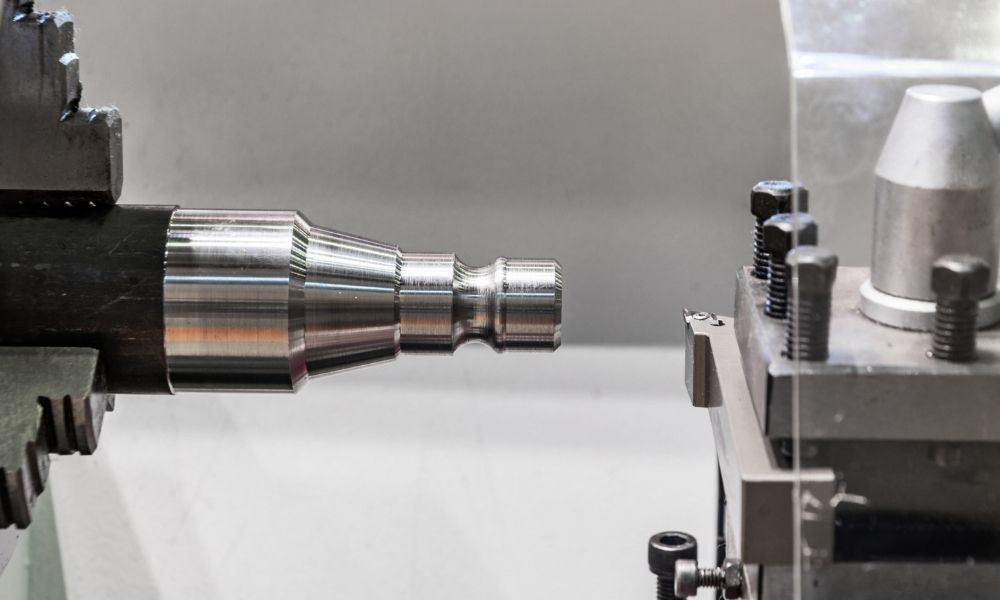

Precision is the key when machining. Whether you are cutting a small part or manufacturing heavy industrial components, keeping the workpiece secure is the key to accuracy. This is where the lathe chuck becomes important. A lathe chuck is a clamping tool fixed on the spindle of a lathe that is used to secure a workpiece when it spins at high speed.

Over the years, machinists and manufacturers have used various lathe chuck types to fit various tasks, ranging from straightforward three-jaw mechanisms to hydraulic and magnetic lathe chuck technologies. The appropriate choice of chuck will depend on the size, shape, and material of the workpiece and the desired level of precision.

In this blog, we shall discuss the prominent lathe chuck types, their characteristics, and applications in machining and shall enlighten you as to which one is ideal for your needs.

The Role of Lathe Chucks in Machining

Think of operating a lathe without an appropriate chuck, it would be almost impossible to hold the workpiece, much less provide precision. The lathe chuck jaws clamp the material securely, keeping it centered and balanced while rotating. Without stability, the finished product might have poor finish, incorrect sizes, or even lead to unsafe working conditions.

Lathe chucks enable machinists to work with a variety of shapes, ranging from cylindrical rod to irregular castings. Lathe chucks also enable the user to change operations in a matter of seconds without wasting time or effort.

Common Lathe Chuck Types

There are a few different lathe chuck types that are created for specific machining purposes. Let’s learn more about the most popular ones and how they are used.

1. Three-Jaw Self-Centering Chuck

Three-jaw chuck is likely to be the most common of all in workshops. It has three lathe chuck jaws that slide as a group when adjusted, automatically centering the piece being worked on. This makes it great for cylindrical or hexagonal parts where symmetry is essential.

Applications:

- Turning shafts, pipes, and rod.

- General-purpose machining where rapid setup is needed.

- Great for beginners because of ease of operation.

The disadvantage is that three-jaw chucks are less accurate compared to other varieties, and they do not hold square or irregular workpieces well.

2. Four-Jaw Independent Chuck

In contrast to the three-jaw type, four-jaw chuck has jaws that can move independently. This makes it possible for machinists to hold securely square, rectangular, or irregularly shaped workpieces.

Applications:

- Machining asymmetrical workpieces.

- Possessing greater precision when manually aligning components.

- Holding heavy-duty components that need increased clamping force.

While setup is more time-consuming, the four-jaw chuck is multifunctional and ideal when accuracy alignment is essential.

3. Combination Chuck

The name tells the story: combination chucks combine aspects of self-centering and independent chucks. They can be moved all jaws at once or each jaw separately, providing versatility for various shapes and machining operations.

Applications:

- A good choice for workshops that work on both symmetrical and irregular work.

- It minimizes the changing of chucks, hence reducing handling time.

4. Magnetic Lathe Chuck

For thin or sensitive workpieces that are troublesome to clamp using standard jaws, the magnetic lathe chuck is an important option. Rather than using mechanical pressure, it applies magnetic force to secure ferromagnetic materials.

Applications:

- Holding thin plates or sensitive workpieces.

- Precision grinding or finishing operations.

- Avoiding distortion that could happen with mechanical clamping.

Though very effective for particular tasks, magnetic lathe chucks are restricted to ferrous materials and cannot grip non-magnetic metals such as aluminum or brass.

5. Collet Chuck

A collet chuck employs a sleeve (collet) to engage the workpiece. The collet clamps on the material when compressed, offering excellent concentricity and holding capacity.

Applications:

- High-speed precision cutting.

- Holding small-diameter workpieces such as rods, pins, and bolts.

- Often used in CNC machines for repetitive operations.

Collet chucks, however, are not appropriate for big or odd shapes since they are primarily intended for regular cylindrical shapes.

6. Drill Chuck

A drill chuck, typically fitted to the tailstock, is intended to hold drill bits or reamers but not the workpiece itself. It supplements the lathe functions by allowing precise drilling work.

Applications:

- Turning holes in the center of rotating workpieces.

- Holding small tools such as taps and reamers.

Though not a main chuck for material holding, its function in lathe work is unavoidable.

7. Hydraulic and Pneumatic Chucks

These high-tech chucks employ hydraulic or pneumatic pressure to provide rapid clamping and unclamping. They are primarily applied in automated and CNC settings where speed and repeatability are paramount.

Applications:

- High-volume production runs.

- Situations calling for repeatability and uniform clamping pressure.

Their greater expense confines them to specialized industrial use.

Understanding Lathe Chuck Jaws

No matter the type of chuck, lathe chuck jaws are actually the true points of contact that hold the workpiece in place. Jaws may be soft (for precision or delicate work) or hard (for heavy-duty use). Some chucks provide for jaw replacement so they can be versatile for various shapes and materials.

For example, a pipe machinist can utilize specialty jaws that exclude slipping, whereas a jeweler would depend on soft jaws for precision when working on delicate items.

Points to Consider When Selecting a Lathe Chuck

Depending on the right chuck is a function of several factors:

- Shape of the Workpiece – Cylindrical workpieces require three-jaw or collet chucks, while irregularly shaped workpieces might need a four-jaw or combination chuck.

- Precision Requirements – For close tolerances, collet or four-jaw independent chucks are suitable.

- Material Type – Delicate or thin ferrous materials are suited with a magnetic lathe chuck.

- Production Quantity – In mass production, hydraulic or pneumatic chucks are more efficient.

- Budget – Lighter chucks such as three-jaw units are economical, whereas sophisticated chucks need more investment.

Applications of Various Lathe Chuck Types

To understand their significance better, let us see how different industries utilize different lathe chuck types:

- Automobile Industry – To make shafts, gears, and engine components, where precision and strength are critical.

- Aerospace Industry – Collet chucks for high-speed machining of high-strength, light-weighted materials.

- Toolmaking – Four-jaw chucks enable the making of non-cylindrical parts and special tools.

- Sheet Metal Work – Magnetic lathe chuck systems are utilized to hold thin sheets firm for finishing.

- General Engineering – Three-jaw and drill chucks are common for normal machining operations.

Benefits and Drawbacks of Lathe Chucks

Benefits:

- Secure clamping for precise machining.

- Flexible for various shapes and sizes.

- Fast setup and flexibility of operations.

Drawbacks:

- A few chucks (such as magnetic or collet) are restricted to certain materials or shapes.

- Setup time can be more for four-jaw independent chucks.

- Sophisticated features such as hydraulic systems may be costly.

Lathe Chuck Maintenance

In order to be long-lasting and precise, lathe chucks need maintenance:

- Clean lathe chuck jaws regularly to avoid accumulating debris.

- Lubricate moving parts to minimize wear.

- Verify alignment and concentricity to prevent machining errors.

- Replace jaws that have worn out as needed.

A properly maintained lathe chuck not only provides consistent outcomes but also guarantees the safety of operators.

Emerging Trends in Lathe Chuck Types

As machining improves, lathe chuck types are also changing. Intelligent chucks with sensors and IoT are being designed to measure clamping force and sense wear automatically. This provides enhanced safety and increased productivity, particularly in automated setups.

Furthermore, composite lightweight materials and improved alloys are being utilized for more effective and long-lasting chucks. Magnetic lathe chuck and hydraulic integration is also anticipated to increase, which will provide machinists with more versatility.

Conclusion

From the humble three-jaw chuck to complex magnetic lathe chuck systems, the lathe chuck world is vast and very specialized. Each one has a specific application, so it is important to pick the correct one according to your machining needs.

Whether you are a hobbyist, a small workshop, or a large industrial setup, knowing the various chucks and lathe chuck jaws can significantly enhance efficiency, precision, and safety. Not only does a proper chuck provide a good grip but also brings the overall quality of your work to the next level.

As machining advances, the lathe chuck will continue to be a benchmark of precision engineering, keeping its head down and holding firm, shaping the future of manufacturing.